Eco Friendly Home & Lifestyle, HandMade Bags, Home Decor Rural Livlihood

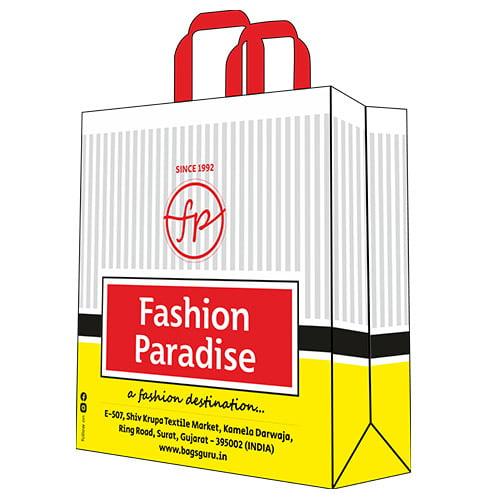

Fashion Paradise White Non Woven Shopping Bag W 15” x H 16.5” x G 5”

₹14.5

We have designed & manufactured this 3 side gusset bag with non-woven fabric for a retailer named “Fashion Paradise”. A color combination of yellow, grey & black is taken as per the brand’s requirement.

- Description

- Additional information

- Reviews (0)

- Q & A

- Sustainability Remark

- More Offers

- Store Policies

- Inquiries

We have designed & manufactured this 3 side gusset bag with non-woven fabric for a retailer named “Fashion Paradise”. A color combination of yellow, grey & black is taken as per the brand’s requirement. The bag can be customized in 70 GSM & 80 GSM fabric thickness.

Product Specifications

| Item | Description |

|---|---|

| Bag Colour | White |

| Bag Size | XL |

| Capacity (kg) | 10-12 kg |

| Material | Non Woven Fabric (100% Virgin) |

| Printed | Yes |

| Printing Process | Flexo Printing |

| Recyclable | 100% Recyclable |

| Reusable | Yes |

| Dimensions | 5 × 15 × 16.5 mm |

|---|

You must be logged in to post a review.

Q & A

Ask a question

There are no questions yet

1. Material Composition

- Non-Woven Fabric: The bag is made from non-woven polypropylene, a synthetic fabric that's produced without weaving. This material is often chosen for its durability, lightweight nature, and recyclability.

- Recyclability: Polypropylene is recyclable, which means the bag can be processed into new products at the end of its life cycle, reducing waste and resource consumption.

2. Production Process

- Lower Energy Consumption: The manufacturing process of non-woven polypropylene generally requires less energy compared to traditional woven fabrics. This is due to the absence of the spinning and weaving processes, which are energy-intensive.

- Reduced Chemical Use: The production of non-woven fabrics often uses fewer chemicals and dyes, further lowering its environmental impact.

3. Durability and Reusability

- Longevity: Non-woven polypropylene bags are durable and can withstand repeated use. This longevity reduces the frequency with which new bags need to be produced, leading to lower overall resource use and waste generation.

- Reusability: By encouraging the use of reusable shopping bags over single-use plastic bags, the environmental impact is significantly reduced.

4. Carbon Footprint

- Efficient Production: The production process of non-woven polypropylene bags typically results in a lower carbon footprint compared to the production of conventional plastic or textile bags. This is due to the energy efficiency of the non-woven manufacturing process and the reduced need for chemical inputs.

- Long-Term Use: The ability to reuse these bags many times further lowers their per-use carbon footprint, as the environmental impact is spread over numerous uses.

Step-by-Step Carbon Footprint Calculation

- Material Production:

- Material: Non-woven polypropylene.

- Emission Factor: According to studies, the carbon footprint of polypropylene production is approximately 1.8 kg CO₂e per kg of material.

- Bag Weight:

- Assume an average non-woven polypropylene shopping bag weighs about 50 grams (0.05 kg).

- Manufacturing Process:

- Emissions: The production process for non-woven polypropylene is generally efficient. Assume additional emissions of about 0.02 kg CO₂e per bag.

- Transportation:

- Emission Factor: Transportation emissions vary based on distance and mode. For simplicity, assume an average of 0.01 kg CO₂e per bag.

- Use and Disposal:

- Reusability: If the bag is used 100 times, the per-use carbon footprint would be:

Summary

The total carbon footprint of a single Eco Fashion Paradise White Non-Woven Shopping Bag is approximately 0.12 kg CO₂e (120 grams CO₂e). When considering reuse, the per-use carbon footprint is much lower, around 1.2 grams CO₂e per use. - Material Production:

No more offers for this product!

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.